Why Frozen Food Packaging from Entrepouch Matters: The Critical Role of Frozen Food Packaging in Preserving Quality

Frozen food has become a staple in modern households and businesses alike. From frozen vegetables and ready-to-eat meals to premium frozen chicken, the demand for safe, high-quality frozen products continues to rise. But while the products themselves are essential, there is an equally critical factor that often goes unnoticed, which is frozen food packaging.

At Entrepouch, we understand that packaging is not just a protective shell. It is a science-driven solution that ensures freshness, safety, and quality preservation from production to the customer’s freezer. In this article, we’ll dive deep into why frozen packaging matters, how it impacts product shelf life, and the innovations shaping the future of frozen goods packaging.

1. Why Frozen Food Packaging is More Than Just a Wrapper

When you pick up a bag of frozen chicken or a pouch of frozen peas, what you’re really holding is a barrier of protection designed to preserve freshness and quality. Unlike packaging for dry goods, frozen food packaging must withstand extreme cold, prevent moisture intrusion, and resist tearing during storage and handling.

Without proper packaging, frozen food is vulnerable to:

Freezer burn (caused by dehydration and oxidation).

Texture degradation (leading to soggy or tough food after thawing).

Loss of nutritional value (especially vitamins sensitive to oxygen exposure).

Contamination risks during storage or transit.

This is where Entrepouch’s frozen goods packaging solutions make a difference. Our materials and designs are engineered to maintain quality while ensuring that businesses meet food safety and compliance standards.

2. The Science Behind Frozen Packaging

Frozen food packaging is all about maintaining the delicate balance between barrier protection and product integrity. Let’s break down the science:

a) Moisture and Oxygen Barriers

Exposure to air is the primary cause of freezer burn. High-quality packaging films with strong oxygen barriers prevent oxidation, while moisture-resistant layers protect against ice crystal formation.

b) Temperature Resistance

Frozen packaging must remain durable and flexible even at sub-zero temperatures. Low-quality plastics may crack, but Entrepouch materials are tested for durability in cold chain logistics.

c) Sealing Technology

A good seal is non-negotiable. Vacuum sealing or tight resealable zippers ensure minimal air pockets, extending shelf life and maintaining taste and texture.

d) Product-Specific Solutions

Different frozen products need different packaging solutions. For instance:

Frozen Chicken Packaging requires thicker, puncture-resistant materials to handle sharp edges and bone fragments.

Frozen Vegetables need lightweight, flexible pouches for easy portioning.

Ready-to-Eat Meals benefit from microwavable or oven-safe packaging that ensures convenience for consumers.

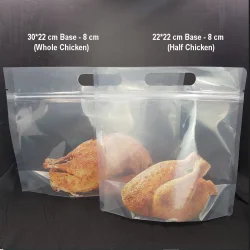

3. Why Frozen Chicken Packaging Deserves Special Attention

Chicken is one of the most widely consumed frozen proteins worldwide, but it is also highly perishable. Poor packaging can lead to faster spoilage, bacterial risks, and flavor loss.

At Entrepouch, we offer specialized frozen chicken packaging solutions that focus on:

Leak-proof protection to avoid contamination during storage.

High-puncture resistance to withstand bones and sharp edges.

Odor-lock technology that prevents unwanted smell leakage in freezers.

Clear labeling space for nutritional info, branding, and cooking instructions.

By using advanced frozen packaging materials, chicken producers and distributors can extend product shelf life while ensuring safety and customer satisfaction.

4. Sustainability in Frozen Goods Packaging

Sustainability is no longer optional. Consumers are increasingly choosing brands that prioritize eco-friendly solutions, even in the frozen food sector.

Entrepouch leads the way with sustainable frozen goods packaging by offering:

Recyclable films and pouches that reduce plastic waste.

Compostable materials where applicable, without compromising barrier protection.

Lightweight packaging designs to minimize transportation costs and carbon footprint.

Balancing sustainability with food safety is challenging, but with advanced material science, eco-conscious frozen packaging is becoming a practical reality.

5. Branding and Marketing Through Packaging

Frozen packaging is not only functional — it’s also a powerful marketing tool. In crowded supermarket freezers, packaging is often the first thing that captures consumer attention.

Entrepouch provides customized designs that combine durability with branding impact:

High-definition printing for vibrant brand logos and imagery.

Transparent windows to showcase product freshness.

Convenient formats such as resealable zippers, easy-tear notches, and stand-up pouches.

Whether it’s frozen chicken packaging or snack-sized frozen meals, good design builds trust and reinforces brand identity.

6. Regulatory Compliance in Frozen Packaging

Food packaging must meet stringent regulatory standards to ensure safety. At Entrepouch, our frozen goods packaging solutions comply with global certifications, including FDA, EU, and FSSAI guidelines.

Compliance ensures that:

Packaging materials are food-grade and non-toxic.

Labels meet industry requirements for traceability.

Businesses avoid costly recalls or legal penalties.

By choosing an experienced partner like Entrepouch, businesses can focus on growth while we handle the technical aspects of compliance.

7. How Entrepouch Adds Value to Frozen Food Packaging

At Entrepouch, we don’t just provide packaging — we deliver end-to-end solutions for businesses in the frozen food sector. Here’s what sets us apart:

Material Expertise: Advanced films, laminates, and multilayer pouches designed for cold storage.

Customization: Tailored packaging for different frozen goods, from poultry to ready meals.

Innovation: Smart packaging options with QR codes for traceability and consumer engagement.

Sustainability: Eco-friendly alternatives without compromising quality.

Global Standards: Compliance with international food safety regulations.

Whether you’re a large frozen food manufacturer or a small business specializing in niche products, Entrepouch offers scalable solutions that help protect, promote, and preserve your products.

8. Future of Frozen Food Packaging

The frozen food industry is evolving rapidly, and so is its packaging. Future trends include:

Smart Packaging with time-temperature indicators for freshness tracking.

Minimalist Eco-Packaging using fewer resources while maintaining performance.

Consumer-Centric Designs for convenience and portion control.

Automation-Friendly Packaging to streamline supply chain processes.

Entrepouch is actively investing in research and innovation to stay ahead of these trends, ensuring our clients are always future-ready.

Conclusion

Frozen food packaging is far more than a simple wrapper but it is a critical factor that determines product quality, shelf life, safety, and customer satisfaction. From protecting frozen chicken against freezer burn to ensuring vegetables retain their nutrients, packaging plays a vital role at every stage.

Entrepouch is proud to be a trusted partner for businesses seeking reliable, innovative, and sustainable frozen packaging solutions. With our expertise in frozen goods packaging and specialized frozen chicken packaging, we help brands deliver fresh, safe, and high-quality frozen foods that stand out in the market.

Your frozen food deserves the best protection — and Entrepouch delivers just that.